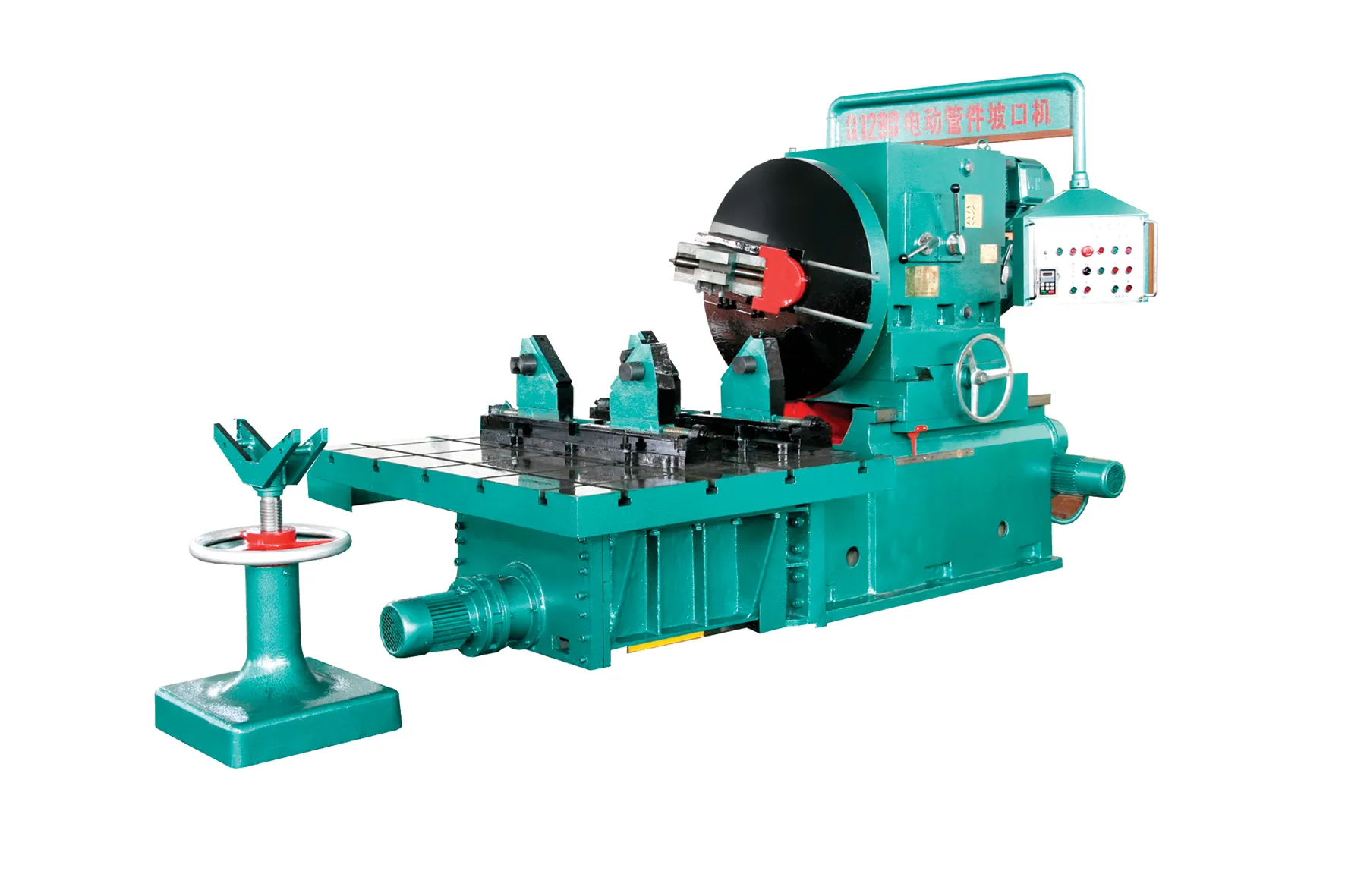

Q1245 Hydraulic Electric Beveling Machine

Category: beveling machine

The Q1245 hydraulic electric beveling machine integrates the advantages of various pipe beveling machines and user requirements. It is designed for beveling seamless steel pipes with diameters from Φ50 mm to Φ425 mm and wall thicknesses from 6 mm to 100 mm.

Product Description

Machine Overview:

The Q1245 hydraulic electric beveling machine integrates the advantages of various pipe beveling machines and user requirements. It is designed for beveling seamless steel pipes with diameters from Φ50 mm to Φ425 mm and wall thicknesses from 6 mm to 100 mm.

This machine uses a standard power head modified for enhanced cutting capability and features a dedicated power box with differential radial feed. Workpiece clamping employs a manual centering device. Alternatively, alignment can be achieved by manually adjusting the power head horizontally and the V-type chuck vertically.

Pipe end beveling can be performed using an angle tool holder with differential automatic feed. For pipes with wall thickness less than 12 mm, a single-pass manual operation using a forming tool is also feasible. Additional accessories include support stands and roller stands, allowing vertical adjustment to align the pipe center with the machine center. The roller stands are manually operated for height adjustment. The machine offers safe, reliable, and convenient operation with broad applicability, making it an ideal solution for pipe-end beveling.

Main Technical Specifications:| 1 | Motor Power | N = 4 kW, n = 960 rpm |

| 2 | Tool Holder Speed | n = 54–206 rpm (6 speed settings) |

| 3 | Processing Range | Pipe Outer Diameter Dr = Φ50–Φ425 mm; Wall Thickness S = 6–100 mm |

| 4 | Angle Tool Holder Adjustment Range | Continuously adjustable between 0–35° |

| 5 | Differential Automatic Feed Rate | 0 or 0.17 mm/rev |

| 6 | Manual Axial Travel Speed | 18.8 mm/rev; Axial Travel Stroke: 200 mm |

| 7 | Bevel Types Supported | Single-V, Double-V, U-shaped, etc. |

| 8 | Tool Holder Diameter | 550 mm |

| 9 | Machine Center Height | H = 1000 mm |

| 10 | Machine Weight | G = 2000 kg |

| 11 | Clamping Method | Hydraulic clamping |