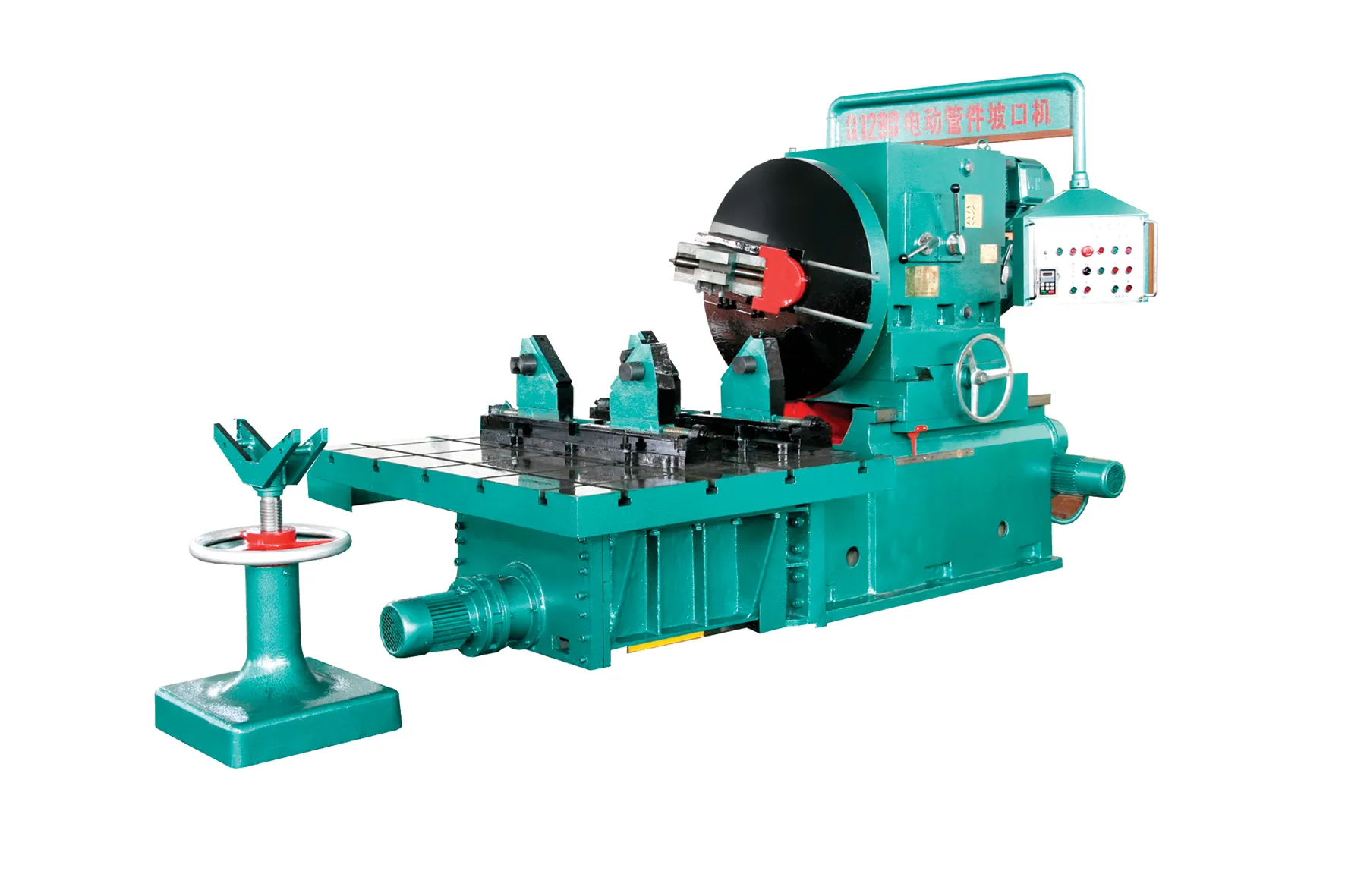

Q12130-III Rotary Table Electric Beveling Machine

Category: beveling machine

This machine is widely used in power plants, oil & gas, chemical, and shipbuilding industries for pipe fitting fabrication and pipeline installation. It is a key piece of equipment for pipe-end preparation prior to welding.

Product Description

Machine Overview: This machine is widely used in power plants, oil & gas, chemical, and shipbuilding industries for pipe fitting fabrication and pipeline installation. It is a key piece of equipment for pipe-end preparation prior to welding. Equipped with interchangeable fixtures, it can process straight pipes and elbows with diameters from φ508 mm to φ1168 mm (20"–46"). The tool holder features an angular tool post suitable for medium-to-high-pressure pipes with wall thickness >14 mm. The angular tool holder is adjusted according to pipe diameter and driven by a differential mechanism for cutting. The clamping system uses a platform structure with flexible clamping to expand processing range and minimize workpiece deformation. Workpiece alignment is achieved by manual horizontal movement of the power head and electric vertical adjustment of the fixture platform. All machine functions are centrally controlled via an operator panel for convenience and reliability.

Main Technical Specifications:| 1 | Motor Power | N = 11 kW |

| 2 | Tool Holder Speed | n = 23–184 rpm (6 speed settings) |

| 3 | Processing Range | Pipe Outer Diameter 400–1150 mm; Wall Thickness 10–150 mm |

| 4 | Angle Tool Holder Adjustment Range | 0–37.5° |

| 5 | Axial Travel Stroke | 400 mm; Variable-Frequency Speed Control:±1.45–14.5 mm/rev (electric) |

| 6 | Axial Rapid Feed Rate | ±313 mm/min (jog mode) |

| 7 | Fixture Work Platform | 2200 × 1600 × 200 mm |

| 8 | Bevel Types Supported | Single-V, Double-V, internal U-bevel, etc. |

| 9 | Tool Holder Diameter | D = 1250 mm |

| 10 | Machine Center Height | H = 1300 mm |