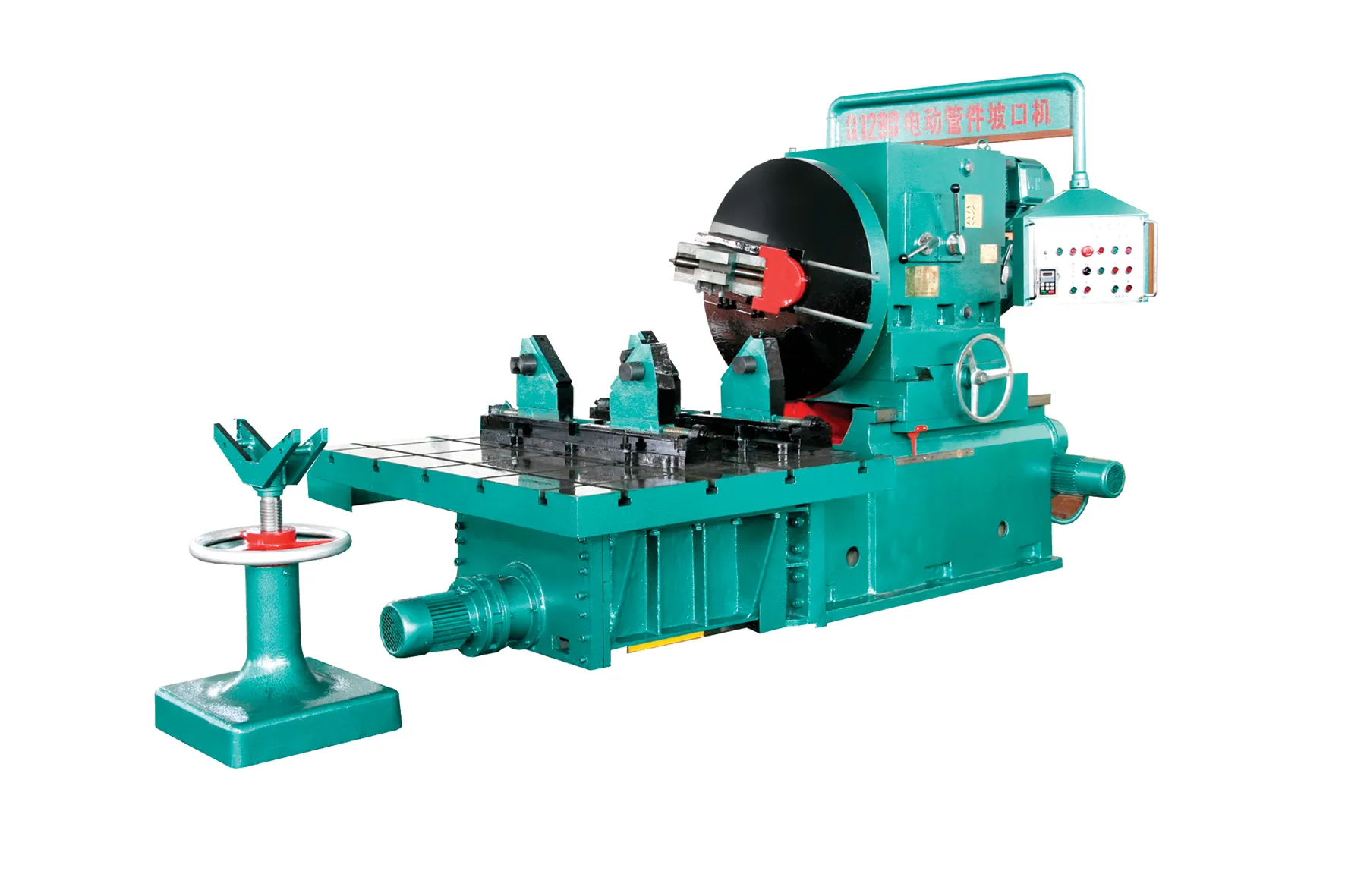

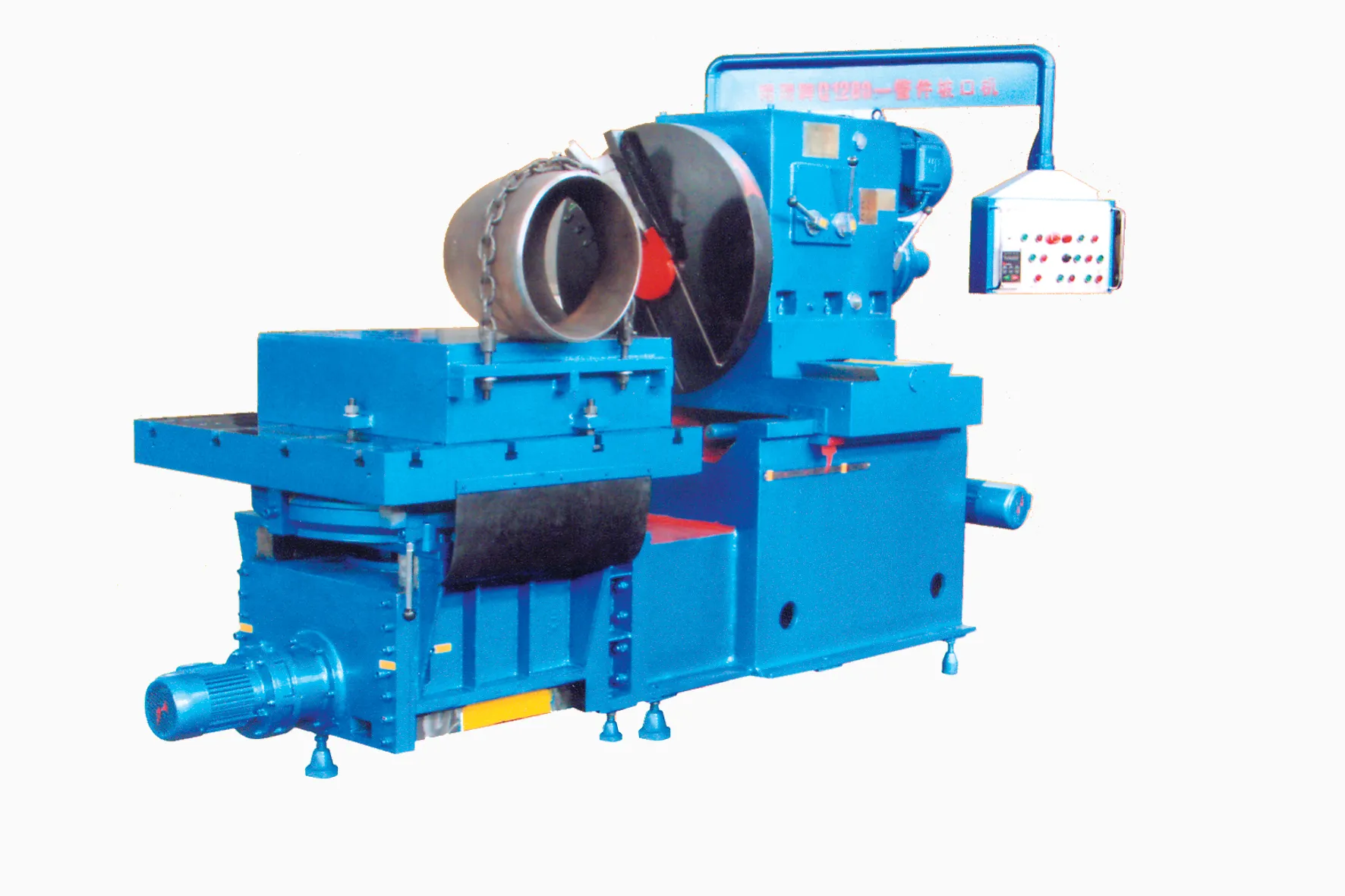

Q1280-I / II Rotary Table Electric Beveling Machine

Category: beveling machine

The Q1280-I and Q1280-II electric beveling machine integrate the advantages of various pipe beveling machines based on user requirements.

Product Description

Machine Overview: The Q1280-I and Q1280-II electric beveling machine integrate the advantages of various pipe beveling machines based on user requirements. Model I is suitable for elbows with diameters from φ325 mm to φ630 mm. Model II is suitable for elbows with diameters from φ530 mm to φ800 mm. Other sizes (φ159–φ820 mm) can be processed by rotating the workpiece. Both models handle fittings such as elbows and tees with wall thicknesses from 10 mm to 150 mm.

The electric longitudinal feed offers both rapid traverse and working feed modes, which can operate independently, simultaneously, or in reverse. The platform height is adjustable for easy workpiece alignment, and rotating the workpiece for double-ended processing is quick and efficient.

Prior to operation, users should select appropriate fixtures based on the workpiece type and diameter, adjust fixture positions accordingly, choose suitable tool holders and cutters based on wall thickness, and set cutting speed and feed method according to pipe diameter and thickness. Pipes with wall thickness under 12 mm can be beveled in a single pass.

These machines are essential for pipe-end beveling prior to welding, offering powerful cutting performance, operational flexibility, and durability.

Main Technical Specifications:| 1 | Motor Power | N = 7.5 kW, n = 960 rpm |

| 2 | Tool Holder Speed | Four settings – 31, 59, 86, 161 rpm |

| 3 | Processing Range | Model I: Pipe OD 325–630 mm, Wall Thickness 10–150 mm Model II: Pipe OD 530–800 mm, Wall Thickness 10–150 mm |

| 4 | Angle Tool Holder Adjustment Range | 0–37.5° |

| 5 | Transverse Travel Stroke | 520 mm |

| 6 | Axial Rapid Feed Rate | ±302 mm/min (electric) |

| 7 | Fixture Work Platform | Model I:1100 × 1100 mm Model II: 1400 × 1400 mm |

| 8 | Bevel Types Supported | Single-V, Double-V, internal U-bevel, etc. |

| 9 | Tool Holder Diameter | Model I: D = 850 mm Model II: D = 1010 mm |

| 10 | Machine Center Height | H = 1125 mm |