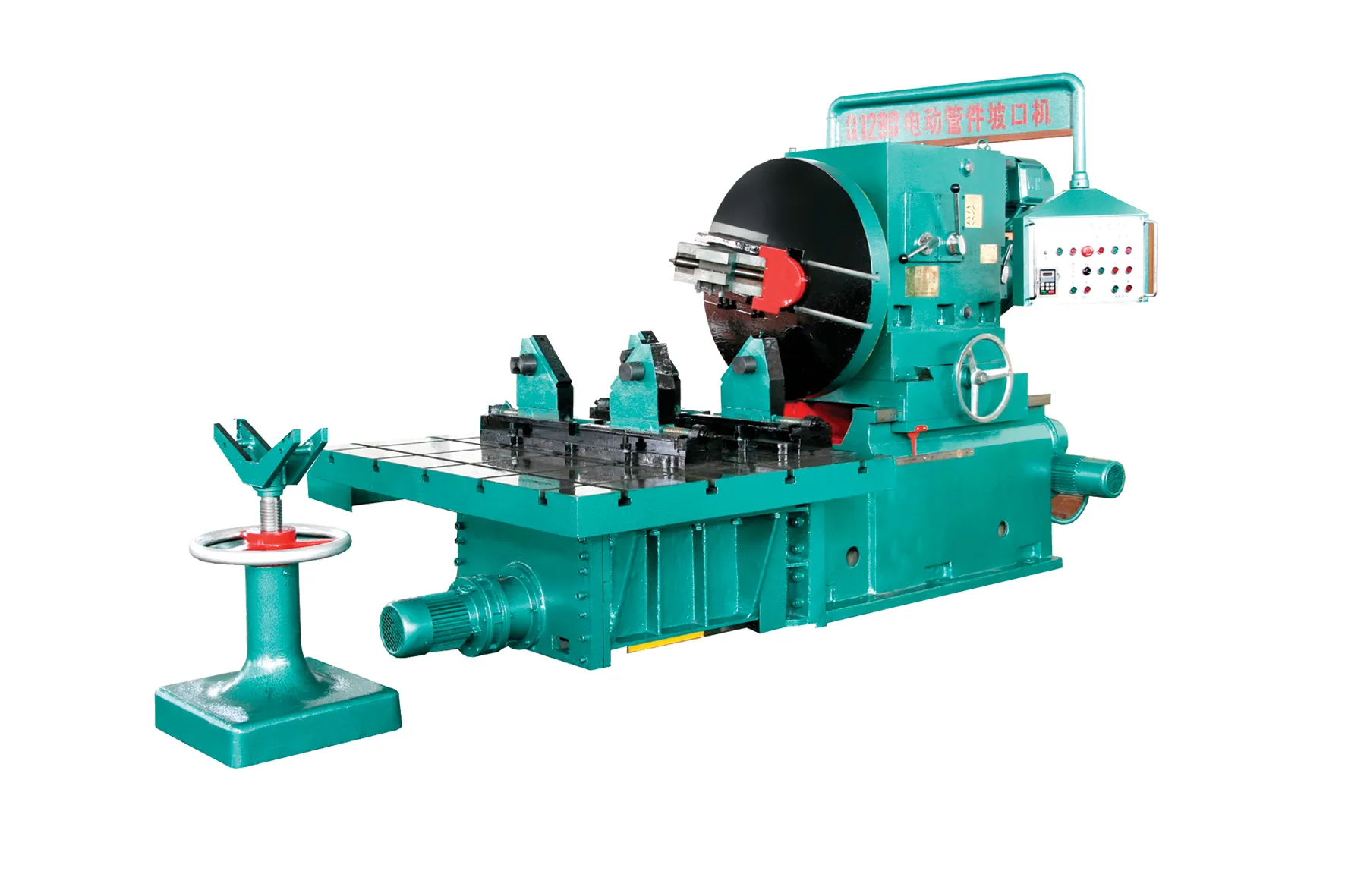

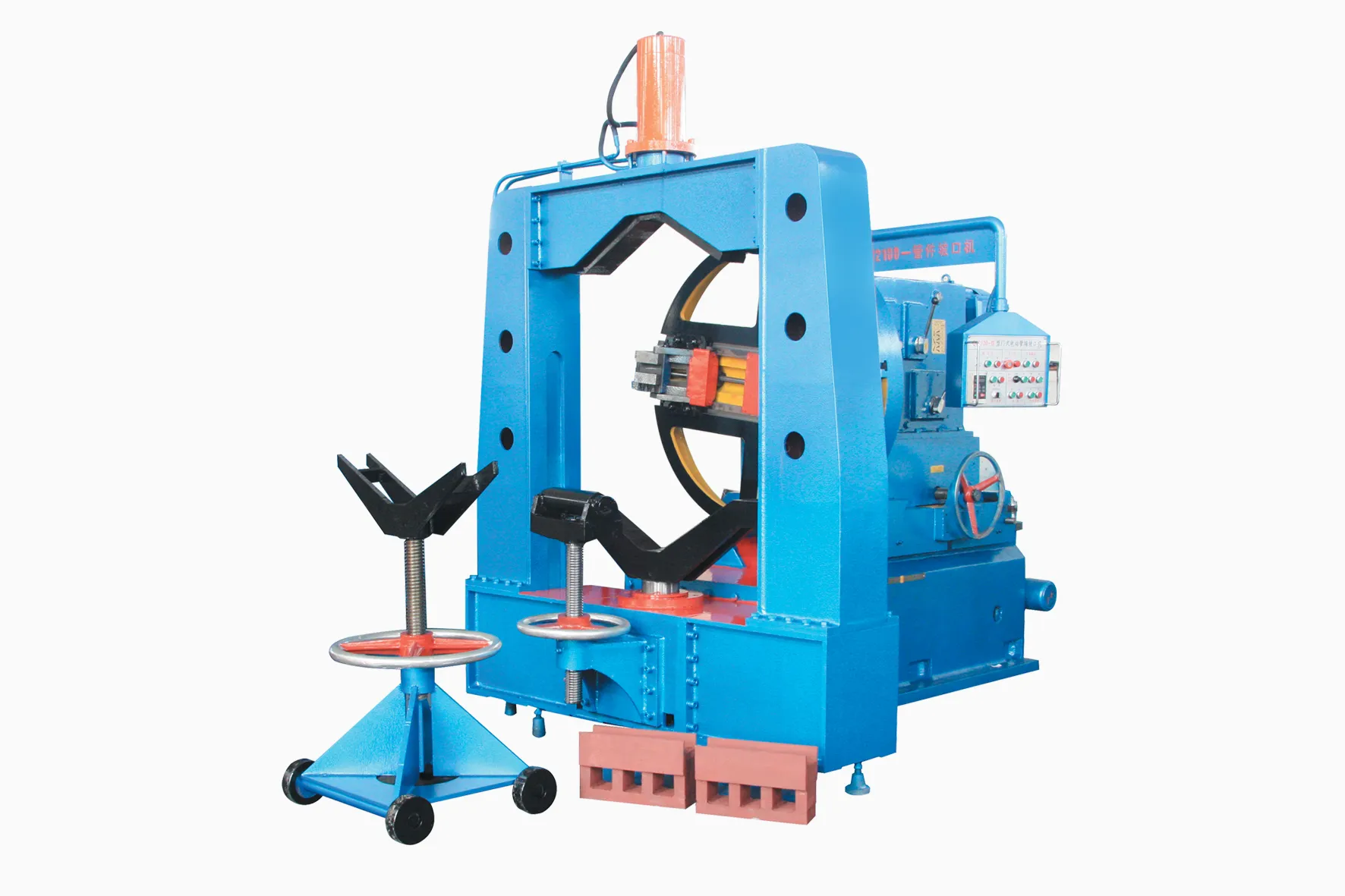

Q1280-II Gantry-Type Electric Beveling Machine

Category: beveling machine

The Q1280-II electric beveling machine incorporates the strengths of various pipe beveling machines and addresses user production needs. It is designed for beveling straight pipe fittings with diameters from 159 mm to 800 mm and wall thicknesses from 10 mm to 180 mm.

Product Description

Machine Overview: The Q1280-II electric beveling machine incorporates the strengths of various pipe beveling machines and addresses user production needs. It is designed for beveling straight pipe fittings with diameters from 159 mm to 800 mm and wall thicknesses from 10 mm to 180 mm.As a critical piece of equipment for pipe-end preparation prior to welding, this machine delivers high cutting force, flexible and convenient operation, and long service life.

The power head provides four gear-shifted spindle speeds and three differential tool-holder feed rates. A motorized rapid advance/retract mechanism is mounted behind the power head, which can operate independently or simultaneously with the differential feed. The tool holder disc allows angle adjustment from 0° to 37.5°.The machine bed includes an electric longitudinal feed system and a manual transverse alignment mechanism. The bed and table assembly enables two longitudinal feed modes—rapid traverse and working feed—which can operate independently, simultaneously, or in opposite directions.

Workpieces are positioned on V-blocks and auxiliary roller stands. The roller stands feature electric vertical adjustment and manual transverse alignment. Hydraulic cylinders provide vertical clamping force. Maximum cutting depth of 5–8 mm ensures high-quality bevel finish. Additional roller stands support longer pipes and allow vertical center alignment.All electrical components are housed in a dedicated electrical cabinet, while control elements are located in a pendant-mounted control box, enabling full machine operation from the console.

Main Technical Specifications:| 1 | Motor Power | N = 7.5 kW |

| 2 | Tool Holder Speed | Four settings – 31, 59, 86, 161 rpm |

| 3 | Processing Range | Pipe Outer Diameter 159–800 mm; Wall Thickness 10–180 mm |

| 4 | Angle Tool Holder Adjustment Range | 0–37.5° |

| 5 | Transverse Travel Stroke | 400 mm; Transverse Adjustment Range: ±50 mm |

| 6 | Axial Rapid Feed Rate | ±302 mm/min (electric) |

| 7 | Bevel Types Supported | Single-V, Double-V, U, X-shaped |

| 8 | Tool Holder Diameter | D = 850 mm |

| 9 | Machine Center Height | H = 1150 mm |